Engine start, troubleshooting, part 1 (Land Cruiser 75 1HZ 4200cc diesel)

- Takashi Iwamoto

- Apr 23, 2021

- 15 min read

Updated: Aug 5, 2023

Welcome to the blog of a cameraman who works across Africa and Japan.

In this blog, the repair notes of the Land Cruiser 75, Trupy, which the manager is riding in Kenya, are posted.

This car has entered its 30th year of production and 19th year of purchase.

It works better and better, but sometimes I feel sick, and this time I had a problem with the fuel line, so I repaired it.

This Land Cruiser Trupy is not sold in Japan, but it is still produced and sold in African countries and Australia.

The 75 is the oldest type among them, and it is a type that uses leaf springs for the front suspension.

This time, I have summarized the engine start malfunctions that occurred during the 18 years, their causes, repair methods, and measures to prevent recurrence.

Content of this blog

Things that cause various problems after riding for many years

Alternator trouble

It is difficult for the engine to start when it is hot

The first start in the morning, the engine vibrates greatly for a while, and white smoke is emitted.

The starter motor does not rotate well even though the battery voltage is sufficient.

The starter motor keeps spinning even though the engine is running

Starter Motor Solenoid Switch Contact Problems

The starter motor turns vigorously, and although it is well preheated, it does not start easily.

Fuel line problem

Still remaining bugs

Fuel line problems continued (next article)

■

1. Things that cause various problems after riding for many years

The car that the caretaker is currently riding is the Land Cruiser, HZJ75 Trupy, born in 1991.

The engine is equipped with a 1HZ, 6-cylinder 4200cc diesel engine.

It's been about 30 years since it was manufactured, and 18 years have already passed since we started riding.

For the number of years, the mileage is still only about 220,000 kilometers.

Actually, the mileage is not fixed.

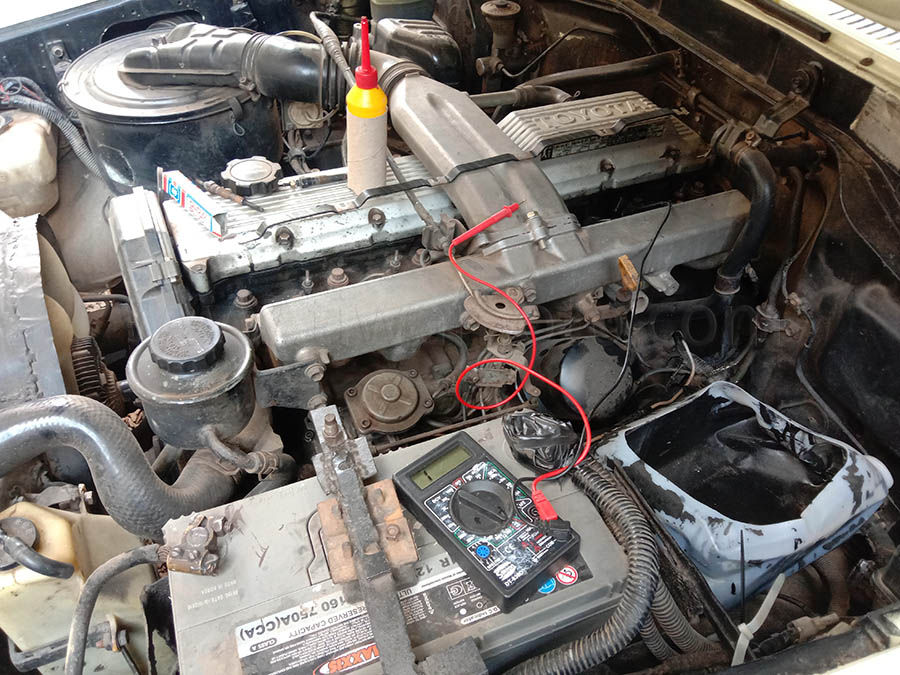

Checking the energization of 1HZ engine and glow plug

After such a number of years, various parts will be worn out, and various things will happen while running.

Keeping the car in good condition while dealing with such a situation is the real pleasure of riding an old car.

If you try to raise what kind of aging symptoms have occurred so far

The brush of the starter motor turned black, it became difficult to turn, the brush was replaced, and one brush was broken.

The inside of the brake master cylinder was scraped after many years of use, making it difficult for the brakes to work. After replacing the piston twice, replace it with a new one.

Brake cylinder of each wheel, liquid leak replacement

Hub, differential, liquid leakage, seal replacement

Clutch cylinder, clutch side piston damage, piston replacement

The speedometer cable is about to break and is replaced, twice

Glow plug for preheating is broken and replaced

Brake booster vacuum leak occurs

Door handle exchange, driver's side twice

I've come up with something that I came up with, but there's no end to it.

Even with such an old car, the stone is the king of safari, Land Cruiser, and most of the consumable parts are relatively cheap, and you can get it even in the countryside, which is quite good in this country.

Moreover, the structure is simple, and it is a sturdy car, and you can usually repair it yourself.

If you repair it yourself, there is no maintenance fee.

The more you polish it, the more it shines and the better it feels.

The fun of driving and the fun of playing with it, the more you ride it, the more you play with it, the more you become attached to it.

So, this time, the manager himself decided to write about the engine troubles and remedies that have occurred so far for the 75 Trupy that he has been petting.

(Please note that all are the experiences of the manager and not the repair manual.)

Basically, when you play with the electrical system, don't forget to remove the negative terminal of the battery to prevent unexpected accidents!

It seems that you need to be careful about removing the battery terminal, which is the current high-tech scene.

Please do everything at your own risk.

2, alternator trouble

The first problem I experienced when I bought it 18 years ago was that the battery voltage dropped and I had to push the engine away.

The cause is the alternator.

Symptoms

As I was running at night, I noticed that the headlights were dim and the voltage was low.

As I ran further, the battery voltage dropped steadily, and eventually the starter motor stopped the engine.

When I checked it with a tester, the voltage did not rise even if the engine speed was increased.

So I found out that the cause was the alternator.

Cause

Immediately before the alternator went wrong, the inside of the engine room was washed with a high-pressure washer, so it is probable that the water at the time of washing was bad.

So I repaired the alternator.

repair

The IC chip was safe, and it was the coil wound on the outside that broke, and it seems that the wire was broken.

The defective coil assembly was removed from the alternator and replaced.

As I learned later, it seems that it was cheaper to buy a rebuilt product.

I was able to learn about the alternator mechanism, partly because I had a hard time.

To prevent recurrence

When cleaning the engine room with a high-pressure washer, it seems that you need to be careful with old cars that have worn out waterproof packing.

After that, water was not used as much as possible for cleaning the engine room.

The relay switches installed for the headlights in the engine room have been replaced many times.

The cause is rust due to the ingress of water in the relay.

Inside the preheat relay inside the bonnet, inside the relay where a large current flows

A large starter motor and preheat relay located beside the battery, and a fairly expensive relay.

It seems that you need to pay particular attention to water here.

This is opened once to remove the rust inside. After all it is caused by moisture.

Even for parts that have been waterproofed, resins such as packing harden over time and the waterproof effect declines over the years.

To avoid extra expense and trouble, it seems better to avoid washing old cars with water as much as possible.

After that, I loaded a lot of electrical components, so I replaced the alternator with a larger one (rebuilt product).

That's about 16 years ago.

Since I replaced it, I haven't had any trouble so far, and it is still steadily generating electricity within the rated voltage.

Of course, since the trouble, the engine room has not been cleaned with a high pressure washer.

When high-pressure washing from the bottom of the body, the alternator is kept out of water.

You may care too much.

3, the engine is hard to start when it is hot

The trouble that the engine does not start is usually the lack of power of the starter motor.

Generally, there are many cold hours in the morning when the battery voltage is low, but I had the opposite trouble.

Symptoms

A symptom that the engine does not start even though the engine has warmed up after running for a long time, the battery voltage is sufficient, and the starter motor is running well.

The engine may stop while driving.

At that time, no matter how hard you try, the engine won't start.

When the engine gets cold, it becomes easier to start the engine.

Interestingly, it's perfectly fine to start in the morning during cold weather.

Cause

After conducting various investigations, I came to the conclusion that this problem was caused by the injector pump.

Removed injector pump

This part, a pump that injects fuel into each cylinder at high pressure at the same time, is the heart of the 1HZ diesel engine and is reasonably priced.

Tracing why the injector pump went wrong, it seems that the cause was cheap and poor quality light oil.

Until that time, I was refueling at the cheapest possible stand, with the selfish judgment that "all the fuel is the same!"

As it was repeated, I think that the injector pump and rotor parts were damaged.

Due to such damage, fuel would not be injected into the cylinder with sufficient pressure.

I always thought that this was the kind of money loss for buying cheap goods.

Eighteen years ago, there were many suspicious stands.

Even now, when I go to rural areas, I sell light oil filled in plastic tanks, but the price is a little cheaper. It is suspected that he is doing some kind of adulterant to make a profit.

According to the story, injector pumps may last less than half a year near the border with Ethiopia.

Only poor quality light oil in such a plastic tank can be obtained there.

repair

For repairs, the rotor of the pump was replaced and the injector nozzle installed on each cylinder was replaced with a new one. The wage is about 45,000 yen.

The problem was solved by replacing the rotor of the injector pump.

The injector pump service was provided three years ago, and the situation at that time was summarized in a video.

To prevent recurrence

Now, considering the brand of the stand and the condition of the engine in the past, I am quite careful about light oil. Recently, T company's light oil seems to be good and I like it.

In African countries, engine performance varies considerably depending on the brand of light oil.

The ease of starting, the smoothness of idling, the power of the engine, and the way black smoke is emitted are all different.

Light oil that runs the engine well will make the engine last longer.

All of these are problems that are unlikely to occur in Japan ...

Will the performance of light oil for cold regions and warm regions in Japan differ?

By the way, isn't tempura oil a burden on the pump?

4, the first start in the morning, the engine vibrates greatly for a while, and white smoke is emitted.

Symptoms

Immediately after starting the first engine in the morning, the engine made a rattling noise for a while and spewed white smoke.

I've come to make such a start.

Cause

Immediately, I instinctively realized that the cause was insufficient preheating of some pistons and glow plugs.

When I checked it with a tester, as I expected, one of the preheat and glow plugs placed on each cylinder was broken.

Of the 6 cylinders, only 5 cylinders were preheated, and the remaining 1 cylinder was not preheated, resulting in a misfire.

The unexploded fuel mist was in the form of being ejected from the muffler.

Since one cylinder did not explode, the rotation balance was lost, causing rattling and vibration and noise.

A little while after starting the engine, the sound and smoke disappear.

Heat is transferred from the surrounding cylinders, and the unexploded cylinders will also be ignited.

repair

At the time of purchase, all glow plugs were replaced.

The six glow plugs I removed were not thrown away, so I replaced the broken ones with them.

Removed glow plug

When I replaced it, the problem was solved smoothly.

When removing this glow plug from the engine block, it is better to let the lubricating oil penetrate sufficiently and proceed slowly over time.

I worked by force and the glow plug broke in the middle

I have seen the article on the net.

If that happens, it's a nightmare without a ton demo!

Work carefully

So, I recently replaced one glow plug, but after waiting for the lubricating oil to fully penetrate, work carefully and carefully with the top crossed so that the force is applied straight with a socket wrench. I proceeded.

To prevent recurrence

There is no particular way to prevent recurrence, but it's a good idea to check the energization status of each blow plug once in a while, as shown in the photo on the cover of this blog.

If it is not energized or it seems difficult to energize, replace it with a new one.

5. The starter motor does not rotate well even though the battery voltage is sufficient.

Symptoms

The starter motor doesn't run well even though the battery voltage is sufficient.

In such a case, the first thing to doubt is the brush of the starter motor.

Removed starter motor

Cause

Previously, I covered the repair situation in the article and video, but after using it for many years, the copper of the brush turns black and it becomes difficult for current to flow.

When the current becomes difficult to flow, the motor rotational force naturally drops.

Even if it doesn't turn black, the number of brushes will decrease, the contact with the comintator will be poor, and the motor will not rotate easily.

Brush discolored after long-term use (left), and new brush (right)

repair

Even though the brush itself is still well connected to the comintator, it should be replaced when it becomes weak.

Also, if even one brush is reduced and the contact becomes poor, it is recommended to replace all the brushes.

This is because copper, which is a brush material, deteriorates over time and its electrical conductivity deteriorates.

Cleaning the contents of the starter motor

If you feel that the rotational force is weakening, it is also recommended to disassemble and clean the commutator and brush.

Carefully check the condition of the brush and whether each connection is loose.

It's a good idea to clean all contacts so that electricity can flow easily.

Use a toothpick to remove dirt from the narrow gaps in the comintator.

When returning it, make sure that it is firmly fitted in the original place such as a waterproof hatch!

Once in the past, one of the wires connecting the brushes came off.

Three brushes were alive, so they move to move, but they lack power.

This was repaired by soldering.

6, the starter motor keeps spinning even though the engine is running

The right side of the screen is the newly purchased solenoid, where it is assembled

Symptoms

I covered this issue a few years ago in an article when I started writing her blog.

The cause is a malfunction of the solenoid switch of the starter motor.

As the starter motor rotates, the rotation of the starter motor is transmitted to the flywheel by gears, and the engine starts.

That's fine, though.

Even when the key was returned to the operating position, the starter motor gear remained connected to the flywheel and the motor continued to rotate.

The starter motor keeps spinning with the idle engine.

Cause

When the key is returned after the engine starts, the small gear connected to the flywheel retracts and the connection between the engine and the starter motor is disconnected.

It is the solenoid that moves such a small pinion gear.

The problem this time was that the solenoid had malfunctioned.

Is it due to long-term use?

repair

When repair was impossible, the starter motor solenoid was completely replaced and the symptom was completely cured.

It's okay to fix it for the time being, but this time another problem arose.

An example where if you fix something, another problem will occur.

7, Starter motor solenoid switch contact problem

When such a solenoid was renewed, problems began to appear in contacts that had never existed before.

Symptoms

Even if I twist the key, the starter motor does not move immediately, and it starts to rotate after a moment.

And even if I return the key, the starter motor does not stop immediately.

It was expected that the cause was that the contacts that move the starter motor and the solenoid were scorched and the contact was poor, and after the connections were made, the contacts melted and stuck together and could not stop.

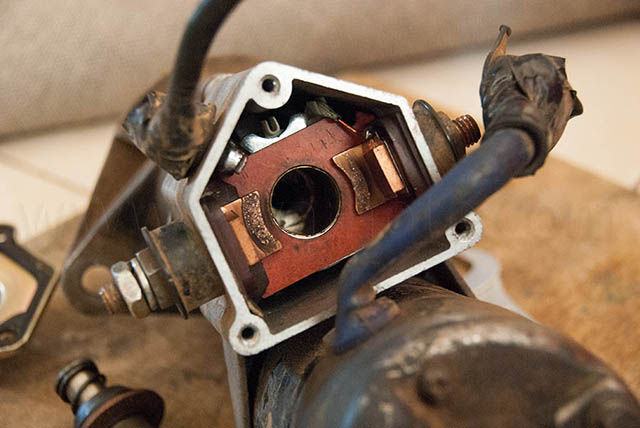

The contacts are darkened, and you can see the traces of melting and sticking.

repair

When I checked the solenoid contacts of the starter motor, as expected, the surface of the contacts was scorched.

As expected, the contacts seemed to melt and stick together.

For the time being, polish the surface cleanly and put it back.

Immediately after the repair, he felt better, but soon the same symptoms recurred.

It seems that the sparks between the contacts could not be stopped just by polishing, and the contact surface immediately turned black with mottle.

At each start, the electrical conductivity of the contacts deteriorates, and the condition becomes worse.

It will burn and the contact will get worse and worse.

Every time I got sick, I disassembled and cleaned it and sanded the surface, but the symptoms did not improve no matter how many times I tried.

This is the place where the thickest cable is connected and the largest current flows, which is extremely dangerous as it is.

Recurrence prevention law

Speaking of contacts, "Tamiya contact grease!"

That's because I used to play radio-controlled models when I was a kid.

So, I decided to apply Tamiya contact grease, which the manager himself used in RC cars that he has been familiar with since he was a child, on the contact surface.

The manager started playing with Tamiya RC car, Wild One when he was in the 5th grade of elementary school. After that, he switched to Kyosho and Optima and made various modifications.

After polishing the disassembled contacts again, Tamiya contact grease was applied to the contacts.

After applying the contact grease, the starter motor was in very good condition and all the problems were completely solved.

Apply Tamiya contact grease to the contacts

It's been about 4 years since I applied the contact grease, and I haven't had any problems.

The last time I changed the brush of the starter motor, it wasn't open.

The moment you twist the key, the starter motor turns, and the moment you return it, the motor stops.

It's a matter of course, but now it works perfectly.

Tamiya contact grease is excellent.

By the way, I tried applying general grease to the contacts once, but the scorching was not improved at all.

8. The starter motor turns vigorously, and although the preheat is sufficient, it does not start easily.

Symptoms

Even though the starter motor is running very well, the engine does not start easily.

This is a recent event, the cause has just been identified and fixed.

The first work I did to find out the cause was as follows:

Checking the air filter and cleaning the blow-up

Replacing the fuel filter,

Confirmation of disconnection of each preheat and glow plug,

Checking the preheat voltage

Even if general measures were taken, the problem was not solved, and the last thing I arrived at was a malfunction of the fuel cut solenoid located in the injector pump.

The fuel cut solenoid is a switch that stops the supply of fuel to the engine and stops the engine by returning the key.

When the battery voltage is applied to the fuel cut solenoid, the fuel flow path is opened and the engine can be started.

On the contrary, when the voltage is interrupted, the fuel is cut off and the running engine stops.

Cause

The symptom that did not start easily this time was that the fuel was not enough for the engine.

Therefore, I suspected that sufficient voltage was not applied to the fuel cut solenoid.

It seems that the solenoid is half open.

repair

Remove the copper wire connected to the fuel cut solenoid and solder a copper washer to the contact.

Originally, I just wrapped the cable around the contact and fixed it with a nut.

The contact in the center of the photo is the repaired part this time, the fuel cut solenoid

This should make it much easier for the current to flow.

Furthermore, both contacts are cleaned with alcohol after removing rust on the surface with a fine file.

Finally, it was reassembled.

After reassembling and testing, it became clear that the fuel cut solenoid had not been sufficiently charged until now, as expected.

When I inserted the key and twisted it to the operation position of the engine before the starter motor turned, I could hear a "click!" Sound that I had never heard before.

Even if you return the key, you will hear a "click!" Sound again.

It seems that the fuel cut solenoid switch has come to move comfortably and powerfully.

Until now, it seems that the solenoid was half-opened due to insufficient current flow.

By repairing the contacts, the engine, which was difficult to start, can now be started comfortably.

As I noticed from the photo above, it is dangerous that the positive (+) is so exposed.

So, after that, I took measures to prevent short circuit with tape on the positive (+) part.

I've done this and I'm feeling pretty good, but sometimes it's still hard to do.

It seems that various factors are intertwined in a complex manner.

Every time I fix it one by one, I get better.

9, fuel line problem

This Land Cruiser 75 Trupy is equipped with two front and rear fuel tanks.

Both have a capacity of 90 liters, totaling 180 liters.

When the tank is full, you can drive deep into the interior without a stand.

This is also one of the reasons why it continues to be loved in Africa and Australia.

Symptoms

Even with all the repairs mentioned above, it's still difficult to start the engine, albeit occasionally.

I suspected that there was a cause for the fuel to be difficult to reach the injector pump.

Cause

The remaining problem is the fuel line.

I decided to check the fuel line to completely solve the engine start problem.

Work done just before writing this article (December-January 2020).

This 75 true pie is equipped with two fuel tanks as mentioned above.

Due to the two fuel tanks, there is a T-shaped branch point in the middle of the fuel line, which makes the structure a little complicated.

75 Trupy Fuel Line Fork

There is a T-shaped branch on both the line from the fuel tank to the engine and the line from the engine to the fuel tank, which connects to the front and rear fuel tanks.

Both branches, a mechanism that can be switched from the driver's seat side with a switch, and a solenoid that switches the fuel flow path.

The two solenoids work together to return unused fuel to the original tank.

Speaking of which, the fact that the fuel in the unused fuel tank sometimes increased was explained by the malfunction of this solenoid switch.

This flow path controlled from the driver's seat side uses the front main tank when the power is off, and when current flows through the solenoid when it is on, it switches to the rear sub tank.

When I went under the car and had my wife operate the fuel tank changeover switch, I found that one switch was malfunctioning.

One, the switch that flows from the engine to the fuel tank barely makes a noise, but the other, the switch on the line from the fuel tank to the engine, makes no noise at all.

This switch, which doesn't switch very often, seems to have gotten sick before I used it.

repair

I tried to remove it and inspect and repair it, but the pipe is stuck and cannot be removed.

The base is made of plastic, so if you force it, it will break easily.

Moreover, expensive parts cannot be forcibly broken.

So, I gave up removing it and decided to repeat ON and OFF from the driver's side for a while.

As this operation was repeated tens and hundreds of times, the operating noise gradually became louder.

Eventually, when I switched the fuel tank, I could hear a considerable noise from my feet even from the driver's seat.

"This should be okay!"

When I started the engine, it felt good, and it started just by turning the starter motor half a turn.

The cause of this may be that the fuel switching solenoid did not work well, the switch stopped halfway, and the fuel flow was impaired.

Measures to prevent recurrence

Solenoids and electric switches may stick if they are not moved all the time.

Just by activating the solenoid switch from time to time, you can prevent such sticking.

If you move the diff lock solenoid switch that moves electrically like this from time to time, you will be able to prevent the trouble of sticking.

10, still remaining defects

After that, the fuel was cut off again, and the injector pump started to bite the air.

My car still had problems with the fuel line.

Various causes were combined to cause a problem.

How many problems were intertwined?

This symptom, cause and countermeasures have become long, so I will cover them in a later blog.

After that, these measures were taken and the engine was started to perfection.

Is it true this time?

How many honesty?

Her wife had a cold eye on her.

More on that in another blog.

■

So, this time I talked about starting the engine.

As I repeated this kind of repair experience, I began to hear the nature of my car and its voice, and I became more and more attached to it.

Until the end Thank you for reading

Comments